![brent wahba, lean sales process]() The Sales function within a company is one of the most important. After all, if there are no sales, there’s no revenue. To paraphrase Peter Drucker, the only purpose for a company is to create a customer. The firm creates customers through sales. While Lean has penetrated almost every function in an organization, the role of Lean in Sales and Marketing is still in its infancy.

The Sales function within a company is one of the most important. After all, if there are no sales, there’s no revenue. To paraphrase Peter Drucker, the only purpose for a company is to create a customer. The firm creates customers through sales. While Lean has penetrated almost every function in an organization, the role of Lean in Sales and Marketing is still in its infancy.

In today’s interview, we present Brent Wahba. He is an influential voice in Lean and a recognized expert in Lean as applied to Sales processes. In this interview, you’ll learn the following:

- Why explaining Lean for Sales and Marketing will be fairly easy to explain to a Lean guy on the shop floor.

- What are the 3 types of sales process in sales and marketing and why Lean must be tailored to each one.

- Why it actually makes sense to begin your Lean journey by applying Lean principles in Sales and Marketing, versus the tradition application on the manufacturing floor.

- What Respect for People looks like in a Sales organization?

We thank Brent for taking the time to speak with us. We have much to learn from his expertise. Enjoy the interview and learn more about Brent after the interview below. And if you wish to contact him to help you in your organization, his contact information can be found after the interview.

Thanks for taking the time to speak with me. Could you please introduce yourself and your work to my readers?

Thanks, Pete. This is quite a pleasure – I love your website. I have had a really interesting career up to this point. I started in R&D at GM, worked in and managed almost every organizational function, and eventually led a global systems business at Delphi. I was fortunate enough to be able to study and apply Lean, Six Sigma, and several other problem solving methodologies along the way, and this led me to my current work as president of a consulting network, Strategy Science Inc., where we help clients learn to improve Sales & Marketing, Product Development, and Strategy on their own.

I am also on the Lean Enterprise Institute Faculty where I teach Lean Sales & Marketing, regularly contribute to the LEI Lean Post, and have published a book titled The Fluff Cycle on solving Sales & Marketing problems. When I am not in airports, I love to do volunteer start-up / small business mentoring through SCORE.

You’re a recognized expert in Lean as applied to the Sales function. If you were speaking to someone on a manufacturing floor that was also a practitioner of Lean, how would you explain what you do to that person? Which areas would you both have in common?

That is a great question and one that I get asked a lot. At its core, Lean is Lean – no matter what value stream you support. It is all about engaging everybody, every day in solving problems, adding more value, utilizing fewer resources, and ultimately achieving the organization’s purpose through helping customers achieve their own purpose. Whether it is on the factory floor or during a sales call, we all have to improve our work while changing the way we think and act.

The difference comes in the type of work we each perform, and I help Sales & Marketing organizations become more efficient and effective at understanding customer needs (stated and latent, technical and emotional), aligning corporate strategies to those needs, providing useful information to the organization so they can create valuable and competitive solutions for those needs, communicating those solutions back to customers, and then facilitating the trial, buying decision, purchase, delivery, and feedback processes to satisfy those customers now, and encouraging them to repeat their purchases and say good things to other potential customers later. Sales & Marketing processes span the entire timeline from a customer’s first exposure to a need, desire, problem, or brand to basically the end of when they could possibly influence anyone else to buy from you.

Sales is a process. Does Lean work the same way on a sales process as it does on a manufacturing process? What are some differences?

One of the biggest mistakes organizations make in trying to implement Lean within Sales & Marketing is by just thinking about it as a transactional, production-like process or a “Sales Factory.” This seems to be a recurring problem as I unfortunately recall the very unsuccessful push for “Engineering Factories” at the beginning of Lean Product Development.

Yes, there are many elements of Sales or Marketing processes that are repetitive in nature like processing sales orders, creating e-mail campaigns, or editing and broadcasting commercials, and these types of processes do benefit greatly from what we have learned in Lean Manufacturing. BUT, we also know that there are different complexities in Sales & Marketing work and some very different types of processes. First of all, Sales & Marketing does not output one type of work for one type of customer – like manufacturing a toaster.

In addition to serving end, paying customers, we also serve Operations, Engineering, R&D, Strategy, Purchasing, Service, etc. with critical information that they all need for their own processes. As we know from Lean Product Development, these “learning processes,” like market research for instance, are managed as variable learning cycles rather than standardized, step-by-step, always-get-the-same-output value streams.

Secondly, a large part of Sales & Marketing work is geared towards influencing both external and internal customers to change their behavior. Nobody woke up one day and out of the blue needed an iPhone, but rather they were educated and influenced over time to desire one because they were valuable. And no doubt Steve Jobs was influenced through many formal and informal processes to decide to put Apple’s resources behind creating the iPhone in the first place.

There is a lot of science behind influence processes that unfortunately doesn’t always align with our common lean thinking. For instance we have learned that websites need a certain amount of webpage “friction” (slowing the reader down) to maximize customer action and conversion. We also know that the human brain rewards itself during the “hunting” process of buying something and thus there can be tremendous value in the journey. If we just blindly pursued the “leanest” possible website or shortest possible buying experience, we could be losing sales.

So the fact that we have 3 types of processes in Sales & Marketing makes applying Lean more challenging, but also more interesting. There is a lot of opportunity for breakthrough improvement.

![sales and marketing processes and lean]()

If given the chance for a lean transformation in one part of a company and the sales function, what is a good argument to begin in sales?

Starting a lean transformation in Sales & Marketing often makes a lot of sense. Most of us were taught to start in Manufacturing because it is close to the customer and easier to demonstrate a quick success. Unfortunately, Operations doesn’t often have the bandwidth to complete their day jobs, perform improvement work, and then try to push Lean upstream into other functions like Sales or Product Development. No matter how lean the Ops folks get, they still receive hard to manufacture product designs from Engineering, uneven order schedules form Sales, and don’t have a clear definition of what customers truly value from Marketing.

If we start our lean journey in Sales & Marketing, however, we not only improve our own work, but our improvements immediately lead to less waste in the other functions – thus giving them more “capacity” to perform their own improvement work. Sales & Marketing also typically has a better view of what needs to change strategically and that is very critical to aligning the transformation with the business’ needs. It is not talked about much, but there is actually a lot of waste in applying Lean across an enterprise, and we can do a much better job if we put in a little more upfront analysis and planning.

One of the pillars of the Toyota Production System is Respect for People. Within the context of Lean Sales, how is Respect for People put into practice? Do you have some examples that might resonate with my audience?

In Psychology there is a theory of intrinsic motivation called the Self-Determination Theory that not only aligns well with TPS’ Respect for People, but is also very helpful on the social side of problem solving within Sales & Marketing organizations.

The three key elements are basically:

- people need to feel autonomous in their jobs – that they own both how to perform and improve their work

- people need to feel like they are recognized as experts in their trades, and

- people belong and contribute to a larger group with a worthy purpose. When we use this model along with our more conventional Lean tools, we get much better results than a simple process improvement approach.

One example was with a client that “wanted to do Lean in Sales” because management didn’t think revenue was high enough and Sales just needed to “get on board with Lean” to fix that. Sales was definitely not getting much respect. By not assuming that the problems were only Sales-specific issues, and engaging the salespeople themselves in holistic problem solving, however, the improvement team determined that the root cause problems were actually confusing strategic directions from above, a lack of the right portfolio of products to sell, and salesperson fear of having to meet with customers who had overdue deliveries.

Sure there were many little improvements that Sales could and did make, but by eliminating the blaming and then fixing the real problems, the Sales group learned that Lean really could help them solve the entire system’s problems and they felt much more respected.

Another client had a sales manager with poor results, a bad attitude, and no apparent desire to learn Lean. Rather than threaten or punish him, however, this client decided to use Strategy Deployment (Hoshin Kanri) to engage him in sales planning, PDCA, and problem solving. He was shown more respect in that he was now part of a scientific goal setting process (catch ball) rather than just being handed “impossible” targets. His attitude and results turned around very quickly.

On a related note, when the central office coaches come in to “enlighten” Sales & Marketing about Lean and use a lot of manufacturing analogies and Lego simulations, it almost always ends badly. Sales & Marketing need to be engaged by solving their own problems and not disrespected because they don’t naturally draw a direct correlation between a running production line and preparing a quote or meeting with customers.

Let’s discuss Lean culture. What does a lean culture look like and feel like in a sales organization?

Cultures change based on shared problem solving, but there are also different sub-cultures within different functions – even across Sales and Marketing. What “Lean Culture” emerges thus depends on what specific problems an organization faces and how they eventually solve those problems.

Overall, however, I would say that a lean sales organization is more scientific, more engaged in problem solving, and seeks to understand and improve the bigger organizational and market-wide systems they are part of. When I say “scientific,” I mean across many disciplines including buyer psychology, strategy, problem solving, and Complex Adaptive Systems which helps describe how markets and organizations change in unpredictable ways. Also, many people talk about the discipline aspect of Lean, but I have found that it is much easier to let discipline naturally emerge from a problem solving culture than try to force it at the beginning – especially in Sales & Marketing.

Generally, can you share how some of the better known aspects of Lean looks like in the context of Lean Sales? For example, Poka-Yoke, Kanban, Andon in Lean for Sales? Do you have specific examples of each that you could share?

The typical Lean Manufacturing tools definitely have their place in transactional sales processes, but I generally avoid teaching a lot of tools until the team has identified a specific problem that any particular method could help resolve. A critical part of becoming expert problem solvers is wrestling with problems to gain better insight, rather than just reaching for a book or finding a benchmark example to copy.

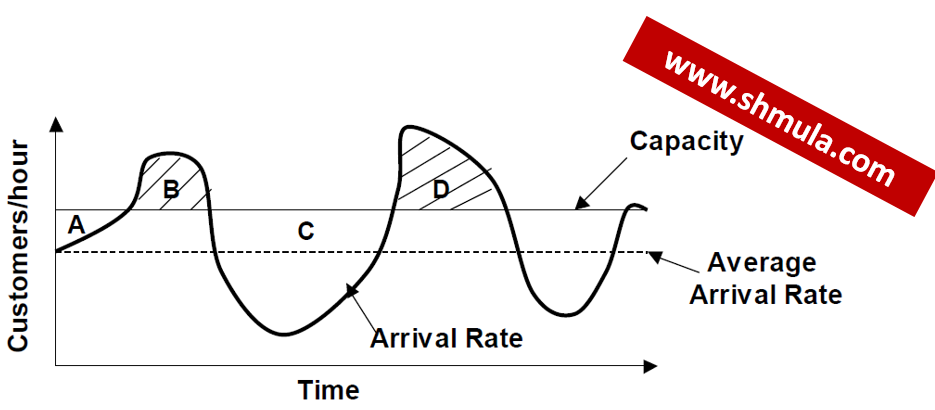

For example, we only introduced Strategy Deployment at Delphi for sales planning and managing the pipeline with PDCA after my team thoroughly defined that we needed a more efficient way to manage both our portfolio and our limited resource salesforce (illustrative example – not real data):

![pdca-lean-sales-process]()

I also have a client in healthcare management that was having trouble aligning capacity with demand. Operations would typically learn about a new contract with only 2 weeks lead time to start, but it required 6 months to hire and train the registered nurses they needed to staff Operations. The solution (along with value stream mapping Operations and creating standard work) was a joint planning / PDCA / visual controls board that showed contract status and potential impact (illustrative example – not real data):

![lean sales value stream]()

What is so nice about their tool is that it embeds many lean tool concepts, yet it was their own solution. Creation and ownership of tools is often a very effective means of driving more engagement.

If we were to identify the 7 wastes in Sales, what would they be? Do you have specific examples Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing, and Defects in Lean Sales?

Everybody has their favorite 8th or 9th waste, so let me start with mine. The biggest waste of all is a non-value producing strategy because it means that the entire organization, no matter how efficient, is headed in the wrong direction and taking their customers, suppliers, and stakeholders with them. It is a major root cause for many of the other wastes.

As far as the other 8 go (I include Underutilized People as #8), they are so ubiquitous that it doesn’t make a lot sense to try to change them – just give Sales & Marketing-specific examples so they make more sense:

| Overproduction: Making more or sooner than customers need |

- Spamming customers with too much email

- Trying to close a sale too early

- Too detailed proposals

- Making a sale when there is no available delivery capacity

|

| Waiting/Delays: Process is stopped until an upstream process step delivers |

- “Where are those sales leads?”

- “We need more orders – our operation is running at half capacity!”

- “Where’s that marketing study? We need to start our development now”

|

| Motion: Unnecessary people movement |

- “Do I really have to walk all the way downstairs to talk to marketing?”

|

| Transportation: Unnecessary material or information movement |

- “The quote required how many approval signatures?”

|

| Overprocessing: Doing more work than is necessary |

- “The quote requires how many approval signatures?”

- Too many features or functions

- “I surveyed soccer dads, too – just in case”

|

| Inventory: Material or information sits idle. |

- “Did we send that quote back to the customer yet?”

- “Do you think that color trends study we did 5 years ago is still good?”

|

| Defects: Material or information does not meet customer needs |

- Fluff

- “That’s not what I ordered!”

- “Your graphics ideas are great, but seriously, we really need to know how far your plan can fly before refueling”

|

| Underutilized People: Not getting the most out of people (wasting their time) |

- “No I didn’t call the customer yet – I spent all morning on my internal PowerPoint”

|

In working with sales organizations, what is their receptiveness to lean principles? Is there resistance? If so, what are the main reasons for resistance?

In my experience, there is little resistance to the actual Lean principles, but resistance does form strongly over time because of the way Lean is introduced or informally observed. Typically, Sales is the last part of the organization to start any lean projects and that gives them a lot of time to hear about many examples that don’t really apply to them. They fear that Lean is going to turn them into “Japanese-speaking robots,” which of course couldn’t be further from the truth, and we’ve already talked about the dangers of trying to create a “Sales Factory” to solve the wrong type of problem.

But if we start our Lean discussion around the things that really matter to Sales & Marketing practitioners and achieving their goals – solving customer problems, creating products and services that customers want to buy, making their own work and selling lives easier, and improving their interface with other parts of the organization, the acceptance is very high.

In the sales world, there are many well-known and accepted selling methodologies like Sandler, SPIN, and Consultative Selling that are nothing more than standardized sales processes with integrated learning loops. This is exactly what Lean creates for Sales & Marketing, but it is a custom solution to a company’s particular problems which results in even more efficiency and effectiveness. In my travels, I meet many Sales & Marketing practitioners that are already lean by their nature and thought processes and don’t even know it yet.

Given a typical sales funnel, can you share how someone with a lean worldview would view that funnel?

I am oversimplifying here, but most organizations look at two major problems in their funnels:

- trying to cram more prospects into the mouth – with hopes that more customers will come out the other end, and

- trying to prevent more potential customers from leaking out along the way to conversion. Somehow it becomes Sales’ job to manage those customers through that funnel like they are cattle or something.

A Lean view would provide a more holistic, enterprise-wide solution. We would better understand how our unique capabilities could provide more value to the right customers, only pursue those right customers, and create a constant learning process along the strategy / product development / selling / delivery / service path so we fine-tune our value while simultaneously educating and influencing our customers.

When we get to the end of something that looks more like a pipe than a funnel, there would be many fewer surprises so we would have much higher confidence and less unevenness in what our production requirements are going to be, and know what elements of value have the most leverage for customer satisfaction and repeat purchase. And when we get really good at understanding the technical and emotional attributes of customer value, our customers become our salespeople and help spread the word for us. This is called “flipping the funnel” in the social media world.

![customer journey, lean sales process]()

Let’s suppose Lean for Sales can actually make the sales process more efficient. But can Lean help the sales function generate more sales? Can applying Lean in Sales help to increase conversions? How?

Definitely! There are two major parts to this. First of all, if we better understand what customers value, we will develop better products, services, and operational capabilities that provide that value. This will naturally lead to higher sales. Also, within the selling process we will be providing more valuable information to those customers at the right time, place, format, and quantity to help them make better buying decisions that include our offerings. Secondly, only after we understand value can we understand waste, and can thus can target our efforts towards the activities that really do lead to more sales.

The department store magnate, John Wanamaker, famously stated “Half the money I spend on advertising is wasted; the trouble is I don’t know which half,” but I think he was wildly optimistic. I, as much as anybody, love those entertaining Super Bowl commercials, but the trouble is that the vast majority don’t lead to higher sales or even better brand perception. There is a ton of waste in just promotion and advertising – we need to leverage that science of Consumer Psychology along with our Lean concepts so that we don’t just streamline our waste.

How do you know if Lean for Sales is adding value to the firm? Can you share some results from your prior work – perhaps a before and after would be instructive.

Everybody wants to measure sales $s (and yes, there are examples of how Lean helped grow sales by 30 – 100%), but that just proves my point that most organizations aren’t looking at how Lean helps entire enterprises perform as interrelated systems. If we have horrible products that we can’t deliver to save our lives, then getting more efficient at selling isn’t going to help our long-term growth or even the short-term bottom line – we are just going to get better and faster at alienating customers.

Sure we all want more sales, but rarely are our problems so simple that tweaking a value stream or adding some tools is going to make a significant or lasting difference. Success in any part of Lean comes from identifying and solving the most critical organization-wide problems and then continuing to find the next organizational bottleneck.

When Delphi was spun-off from General Motors, we had a very pressing need to diversify our customer and market bases. We knew our GM business was going to decrease, so we had to find a way to offset it before we could even consider growth. In my product lines we started by approaching many, many potential customers and we essentially got nowhere – despite a lot of hard work. As we applied Lean, overhauled our strategy, targeted specific markets and customers, developed customer-specific value propositions, and then developed new products / services / global lean manufacturing capabilities to implement those value propositions, we quickly gained traction – reducing our development and quotation lead times by 50 and 80%, and capturing 10 of 10 target customers in 7 of 7 target markets.

It was almost too good to be true. Oh, and we did it with 25% fewer resources and 1 less management layer. But these were our specific problems and solutions – “your results may vary.”

So the proof comes when a company identifies their particular bottlenecks and then solves them. Some other examples include: 30% reduction in new business analysis lead time, implementing an enterprise-wide Voice-of-the-Customer process to capture customer feedback at every point of contact to better understand total lifetime value, and increasing company-wide capacity utilization by 10% by just better-aligning selling with manufacturing site allocation. Greater sales will eventually come from all these improvements, but in a complex business system there rarely is a quick way to reliably measure only the sales $ effects of any particular actions – there are too many other uncontrollable variables and simultaneous changes.

How can someone learn more if they want to begin applying lean to their sales process?

I would be a horrible salesperson if I didn’t take this opportunity to promote my book, The Fluff Cycle,” or my classes and Lean Post articles at the Lean Enterprise Institute. And I would also be a horrible guest if I ddidn’t plug Shmula.com’s focus on customer experience – a huge part of what Lean can offer to the Sales & Marketing world. Case studies are always interesting, but I caution people to remember that those are particular solutions to some other organization’s particular problems and chances are fairly low that they apply directly to you. The very best way to learn is to experiment, sometimes fail, and then experiment again and again.

Any final words you’d like to share with my audience?

In my 20+ years of Lean, my best advice comes from observing the small % of companies that are truly successful and sustain their progress. The one thing that sets them apart is that they don’t “do Lean,” in the conventional textbook / somebody else’s model & tools approach, but rather they regularly solve important problems, with their own solutions, to advance their business. The goal should never be to become lean, but rather to become a better business – no matter what methods you need to use to get there. When companies do this, Lean naturally emerges from within the organization, and they end up spending far less effort on a better, company-specific solution. One great example can be found here in my article ‘Are We “Doing Lean” All Wrong?

Thank you very much, Pete, this truly has been a pleasure!

About Brent Wahba

![brent wahba, lean sales process]() Brent Wahba learned how to apply Lean and Sigma by spending over 20 years in the automotive industry in a variety of leadership and technical positions at the Delphi Corporation. While there, he headed global product lines, led the creation and implementation of sales & marketing strategies, managed R&D and new product development organizations, and optimized operations – all while developing new applications of continuous improvement methodologies. Today he writes, gives talks, teaches classes, and consults on many topics including Adaptive Strategic Planning, Product Development Process & Culture Change, and Sales & Marketing Problem Solving. His latest work includes the book The Fluff Cycle (And How To End It By Solving REAL Sales & Marketing Problems). Brent is currently the President of the Strategy Science consulting network, and is also on the faculty of the Lean Enterprise Institute where he teaches Lean Sales & Marketing. When he is not travelling around the world, he can be found giving volunteer start-up business mentoring near his home in Dallas, Texas.

Brent Wahba learned how to apply Lean and Sigma by spending over 20 years in the automotive industry in a variety of leadership and technical positions at the Delphi Corporation. While there, he headed global product lines, led the creation and implementation of sales & marketing strategies, managed R&D and new product development organizations, and optimized operations – all while developing new applications of continuous improvement methodologies. Today he writes, gives talks, teaches classes, and consults on many topics including Adaptive Strategic Planning, Product Development Process & Culture Change, and Sales & Marketing Problem Solving. His latest work includes the book The Fluff Cycle (And How To End It By Solving REAL Sales & Marketing Problems). Brent is currently the President of the Strategy Science consulting network, and is also on the faculty of the Lean Enterprise Institute where he teaches Lean Sales & Marketing. When he is not travelling around the world, he can be found giving volunteer start-up business mentoring near his home in Dallas, Texas.

Brent holds a BS in Electrical Engineering from the University of Rochester, an MS in Materials Science and Engineering from the Rochester Institute of Technology, an MBA from the University of Rochester, and has authored 10 patents.

He can be contacted at brentwahba@strategyscienceinc.com or 585.315.7051

The post Lean Sales and Marketing with Brent Wahba appeared first on shmula.

![]()

What’s a Catalog Engineer?

What’s a Catalog Engineer?

The logo design utilizes the first law of subtraction (what isn’t there can often trump what is) with use of a negative space minus sign to denote the act of editing.

The logo design utilizes the first law of subtraction (what isn’t there can often trump what is) with use of a negative space minus sign to denote the act of editing. Matthew E. May counsels executives and teams on matters of strategy, culture, and innovation through his firm, EDIT Innovation.

Matthew E. May counsels executives and teams on matters of strategy, culture, and innovation through his firm, EDIT Innovation. We’re pleased to present to you this interview with our good friend, Mark Graban. Mark is the guy you want on your team when it comes to improving healthcare. As you read this interview, you’ll learn the following:

We’re pleased to present to you this interview with our good friend, Mark Graban. Mark is the guy you want on your team when it comes to improving healthcare. As you read this interview, you’ll learn the following: About Mark Graban

About Mark Graban

I am so excited to present to you this interview I had the opportunity to conduct with Art Smalley. In my mind, Art brings a voice of reason to the rest of the Lean world. He is one of the few Americans to work for the Toyota Motor Corporation in Japan. He worked under one of Mr. Taiichi Ohno’s early students. You can learn more about Art at the end of the interview in his Bio section. In this interview, you’ll learn the following:

I am so excited to present to you this interview I had the opportunity to conduct with Art Smalley. In my mind, Art brings a voice of reason to the rest of the Lean world. He is one of the few Americans to work for the Toyota Motor Corporation in Japan. He worked under one of Mr. Taiichi Ohno’s early students. You can learn more about Art at the end of the interview in his Bio section. In this interview, you’ll learn the following: Continuing our interview series with some of the leading voices in Lean, today we’re speaking with Jeff Gothelf, the author of Lean UX. Applying Lean to user experience is exciting and, in my opinion, is an area of Lean that is sorely lacking attention. Most Lean practitioners focus on operations, but there’s not as much attention paid to the user experience. In today’s interview, you’ll learn the following:

Continuing our interview series with some of the leading voices in Lean, today we’re speaking with Jeff Gothelf, the author of Lean UX. Applying Lean to user experience is exciting and, in my opinion, is an area of Lean that is sorely lacking attention. Most Lean practitioners focus on operations, but there’s not as much attention paid to the user experience. In today’s interview, you’ll learn the following:

Lean principles is being adopted across all business areas. It is, indeed, an exciting time to see so much acceptance. In today’s interview, we speak with Cecil Dijoux, a very influential voice in the world of Lean IT, or Lean for Information Technology. In this interview, you’ll learn the following:

Lean principles is being adopted across all business areas. It is, indeed, an exciting time to see so much acceptance. In today’s interview, we speak with Cecil Dijoux, a very influential voice in the world of Lean IT, or Lean for Information Technology. In this interview, you’ll learn the following: The Sales function within a company is one of the most important. After all, if there are

The Sales function within a company is one of the most important. After all, if there are

I’m very excited to present to you this interview with David J. Anderson. He’s a Management author, consultant & trainer and Pioneer of the use of Kanban Systems in creative & knowledge worker industries. I’m grateful he took the time out of his very busy schedule to spend with us and in answering our questions.

I’m very excited to present to you this interview with David J. Anderson. He’s a Management author, consultant & trainer and Pioneer of the use of Kanban Systems in creative & knowledge worker industries. I’m grateful he took the time out of his very busy schedule to spend with us and in answering our questions.

Yesterday, we interviewed David Anderson, who pioneered the use of

Yesterday, we interviewed David Anderson, who pioneered the use of  Today we hear from a leading voice in Lean for the Office and knowledge work, Dan Markovitz. I’m so excited that he took the time to speak with us today.

Today we hear from a leading voice in Lean for the Office and knowledge work, Dan Markovitz. I’m so excited that he took the time to speak with us today. We are quite pleased to have Dr. Jeffrey Liker speak with us today. If you all turn your eyes to your bookshelves, I’m sure you will likely find a few books for which Dr. Liker has authored. He has helped to bring to a general audience Lean Manufacturing and has gone on to help countless of companies adopt the Toyota Production System in their own operations. We’re very excited that Dr. Liker chose to spend some of his time answering our questions.

We are quite pleased to have Dr. Jeffrey Liker speak with us today. If you all turn your eyes to your bookshelves, I’m sure you will likely find a few books for which Dr. Liker has authored. He has helped to bring to a general audience Lean Manufacturing and has gone on to help countless of companies adopt the Toyota Production System in their own operations. We’re very excited that Dr. Liker chose to spend some of his time answering our questions.

Laura is Summa Cum Laude from the Kogod School of Business (American University), and completed a Master’s degree in Design Management (Savannah College of Art & Design, SCAD). She is currently completing her PhD dissertation in Consumer Psychology, sponsored by the Colombian Government’s Administrative Department for Science, Technology & Innovation (Colciencias).

Laura is Summa Cum Laude from the Kogod School of Business (American University), and completed a Master’s degree in Design Management (Savannah College of Art & Design, SCAD). She is currently completing her PhD dissertation in Consumer Psychology, sponsored by the Colombian Government’s Administrative Department for Science, Technology & Innovation (Colciencias).