The post The Rackspace Customer Experience Secret Sauce: An Interview with Rackspace COO Mark Roenigk appeared first on shmula.

I am very excited to present this interview with Mark Roenigk, the Chief Operating Officer of Rackspace. For those who may not know, Rackspace is a hosting and cloud computing company, that has grown very fast and has created a tremendous amount of customer loyalty and endearment.

I am very excited to present this interview with Mark Roenigk, the Chief Operating Officer of Rackspace. For those who may not know, Rackspace is a hosting and cloud computing company, that has grown very fast and has created a tremendous amount of customer loyalty and endearment.

In this interview, we’ll learn about how Rackspace has placed the customer at the center of their activities and the role the Rackspace employees play in making the organization focused on the customer. We’ll also learn the role of Process Improvement within the context of their internal NPS program, which is also very respected and known for its rigor and effectiveness in helping the firm remain focused on the customer.

I also have a bit of a disclosure: Mark and I have known each other for many years. He has been a very close friend and mentor and I have learned much and continue to learn from him. Aside from being an exceptional professional and executive, he is down-to-earth, humble, and a good man. I’m grateful he’s accepted this opportunity to share with us some of the secret sauce that has made Rackspace such a beloved company and an NPS powerhouse.

Be sure to Share this article with your friends

1. Mark, thanks for taking the time to answer a few questions. For those who may not know Rackspace, can you share a little about the company and also please share with us a little about yourself and what role you play at Rackspace?

Rackspace is a hosting and cloud computing company founded in 1998 in San Antonio. Rackspace is the founder of OpenStack, the standard open-source operating system for cloud computing, and a founding member of the Open Compute Project. We are known for our renowned Fanatical Support, which we deliver to more than 200,000 business customers from data centers on four continents.

I serve as Chief Operating Officer at Rackspace, responsible for the computing platforms on which Rackspace delivers products, services and support. I started my career as an engineer at Compaq before moving into management, later holding senior leadership roles at Microsoft, Intuit, Sirius XM and eBay. I came to Rackspace in 2009 because I was drawn to the culture and the inspiring mission to be one of the world’s leading service company.

2. Rackspace is well known for its fanatical focus on the customer. The first Rackspace core value is “Fanatical Support: Create customer experiences that create emotional attachment”. Why is that important and how does Rackspace accomplish that core value?

Let’s face it; we sell technology, an abundant commodity that can be created, sold and purchased with minimal human interaction from multiple providers. So, being in the technology market, we at Rackspace had to ask: What is our differentiator? What is our claim to fame? How can we add value and keep our customer coming back?

We have chosen Fanatical Support® to serve as that differentiator. At Rackspace, we know that customer satisfaction and building long-lasting relationships with our customers is our most important objective. Satisfied customers will tell their colleagues about Rackspace, becoming promoters for our brand and an external sales force for our company. Therefore, Fanatical Support is essential to our business; it is what lies at the core of our company because we know it’s essential to our success.

Our customers run a lot of very different businesses, and we don’t expect them to all be tech savvy; that’s our job. We ensure that we have diverse talent with deep expertise to help our customers solve problems and learn more about the best solutions for their needs.

3. Let’s talk about your NPS program. When did Rackspace begin its NPS Journey and how is it going?

NPS is a metric that measures customer loyalty by asking them to answer one question based on a scale from 1 to 10: How likely are you to recommend Rackspace to a friend or colleague? We’ve been asking this question in one form or another as far back as 2003-2004 when the original Harvard Business Review article was published. However, we quickly realized that just asking the question and calculating a score doesn’t get you very far. We track customer’s responses to detect positive or negative shifts in their satisfaction, so we can reach out to a customer directly if need be. This way, NPS is not a static number. Instead, it is a real-time assessment of our company’s performance and success. A strong NPS program needs a great deal of underlying discipline in how we analyze feedback and take action.

The program matured a bit more beginning in 2008. Since then, we’ve continued to tweak our approach and each business unit has customized aspects of the program to fit their needs. We also use NPS to examine our internal employee engagement, as well our internal performance on back office functions – what we refer to as “Rackers serving Rackers.” Understanding satisfaction within our own four walls led us to be listed this year as No. 34 in Fortune’s “100 Best Companies to Work For.”

4. Lanham Napier, Rackspace CEO, has called NPS the “greatness metric”. What does he mean by that? Additionally, it’s been said that Mr. Napier reads customer open-ended responses every day. Is that really true? If the CEO connects with customers in that way, how does that customer-centric behavior from the top down affect the rest of the company?

Lanham is a strong communicator – his messages resonate powerfully with Rackers. A critical theme over the past several years has been about the difference between good and great companies, and the focus necessary to ensure a path to ‘great.’ His message is simple and speaks to the fact that so many metrics we see today reflect a company’s path to ‘big’ without representing customer sentiment. Ours is a loyalty strategy, and Lanham believes the path to greatness comes through earning 9’s and 10’s from all of our customers. His specific quote is: “Greatness is achieved when customers say we are great.”

Lanham has been reviewing customer feedback every day for a long time. Transparency is a core value here, and we are very open with customer voice at Rackspace. Randomly selected responses are distributed routinely, and it’s not unusual for Lanham to call these customers directly to say “thank you” or offer his help to customers with negative feedback. The Rackspace Board of Directors also reviews NPS feedback in their quarterly meetings. It’s definitely an effective leadership tool, and it helps hold Rackers across the organization accountable for doing the same. It’s one of several mechanisms for keeping a customer focus.

5. Rackers. What is a Racker? Was the name deliberately chosen? “Customer Service Rep” is the more common title – why is Racker better than using CSR?

Customer service rep explains a job function within a company that involves interaction with customers through technology. At Rackspace, all employees are Rackers, not just those who deal directly with the customer. A Racker is someone who embodies our core values, has a commitment to service and is dedicated to the vision of the company. It is more than a label like lawyer, accountant or customer service representative. Being a Racker allows our employees to create a shared identity despite the job function they perform, and it creates a company-wide sense of camaraderie. In fact, we call our onboarding process “Welcome Home”; symbolizing the ultimate feeling of belonging the moment you start as a new hire. Our customers pick up on this sense of community as well, and it provides a sense of reassurance to know they have such a unified workforce behind them.

6. Rackspace has an internal Lean Six Sigma program. Tell us how NPS and Lean Six Sigma work together at Rackspace to improve the customer experience?

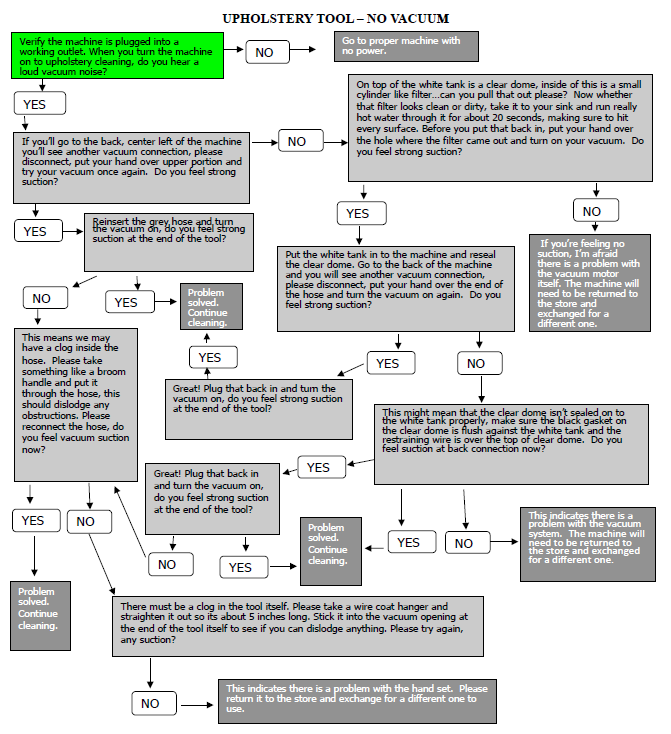

NPS is a critical input to the voice of our customers. Rackspace utilizes NPS feedback to determine high impact areas for improvements in our products and services. Business leaders partner with Operational Excellence (LSS program) and the NPS team to strategize how to make these improvements for our customers. These opportunities are taken to our “Racktivity Room”, a space where cross-functional teams meet to solve problems and innovate. Through a series of “Racktivites” (Lean /Six Sigma / Innovation Games and Program Management Tools), teams create solutions to make these opportunities a reality.

7. Is there anything else you’d like to share?

We have passionate Rackers innovating the industry in Open standards and fanatical support every day, because they are truly passionate about the success of our customers. This kind of culture is the reason the whole industry is buzzing about hybrid cloud right now; a combination of public cloud, private cloud, and dedicated bare metal computing powered behind OpenStack. We are able to offer customers massive gains in performance, reliability, security, and cost-effectiveness that aren’t seen with other service providers. Rackspace is committed to helping our customers change the world- and we will do anything to make sure of it.

Mark Roenigk, Rackspace COO

As Chief Operating Officer, Mark is responsible for the computing platforms on which Rackspace delivers products, services and support. Mark reports directly to Lanham Napier, CEO.

As Chief Operating Officer, Mark is responsible for the computing platforms on which Rackspace delivers products, services and support. Mark reports directly to Lanham Napier, CEO.

An engineer by trade, Mark manages Rackspace’s global infrastructure and associated services such as data center engineering & operations, hardware design & configuration, networking, infrastructure services (storage, backup, and data protection), supply chain and procurement.

He is also is responsible for global security, internal enterprise IT and the customer service tools that enable Rackers to deliver Fanatical Support.

Mark started his career as an engineer at Compaq before moving into management, and later held senior leadership roles at Microsoft, Intuit, Sirius XM and eBay. Mark is regularly requested to participate on expert panels to discuss technology trends, supply chain innovation, net promoter programs and leadership. He has published articles in the fields of leadership, supply chain and digital & physical anti-counterfeiting technologies.

Mark has been a strong supporter of charities dedicated to enriching the lives of children with disabilities. He is on the Board of Directors of Taelor’s House Foundation and supports the Prader-Willi Syndrome Association, Special Olympics and the Boys & Girls Clubs of America.

What does Mark like best about working at Rackspace? The culture. “If you give Rackers a vision and a strategy it will absolutely get done,” he says. “There’s nothing we think we can’t do.”

Mark holds a BBA degree in management from Texas A&M University.

The post The Rackspace Customer Experience Secret Sauce: An Interview with Rackspace COO Mark Roenigk appeared first on shmula.

Adam has more than twenty years of experience in senior executive roles with global and Australian organizations. A natural strategist, he has a developed a deep knowledge of customer, financial and data analysis.

Adam has more than twenty years of experience in senior executive roles with global and Australian organizations. A natural strategist, he has a developed a deep knowledge of customer, financial and data analysis. David Hutchinson is the CEO and co-founder of Symbiant Technologies. He has over 25 years of experience implementing ERP and technology systems in both public and private sector organizations. He has received several awards, including the Richard Drew award for Creative Thinking by 3M Corporation.

David Hutchinson is the CEO and co-founder of Symbiant Technologies. He has over 25 years of experience implementing ERP and technology systems in both public and private sector organizations. He has received several awards, including the Richard Drew award for Creative Thinking by 3M Corporation.