Domino’s Pizza Tracker Process – A Behind the Scenes Look at what actually happens in the Domino’s Pizza Kitchen and how the steps in the kitchen connects to the steps in the Pizza Tracker – the tool the customer interacts with.

If you’ve been reading Shmula for some time, you know my unusual appreciation for “Where’s My Stuff” Visual Management. Well, much has been written about Domino’s Pizza Tracker. And while the customer-facing aspect of the Pizza Tracker is interesting, I was able to capture a rare look at what happens behind the scenes and how each step behind the scenes corresponds with the Pizza Tracker the customer sees on the Domino’s website.

It turns out that what happens in Domino’s kitchen is not that novel, but it works just fine. Nevertheless, the customer-facing side is what the customer sees and what they experience. If the back-end of the process is dirty, nasty, and not all that interesting, it’s a good thing the customer is encapsulated from that.

Let’s see what the Domino’s Pizza Tracker looks like behind the scenes. But first, a reminder on what the customer sees.

Image may be NSFW.

Clik here to view.![]()

Image may be NSFW.

Clik here to view.

Here’s the behind the scenes look at Domino’s Pizza Tracker.

Order Placed

Step 1: Order Capture

An order arrives on a small vintage computer screen. The Domino’s employee views the order and begins the process of manufacturing the pizza.

Prep

Step 2: Pizza Manufacturing

Dough

The Dough is made fresh in the morning and is prepared as a batch – that is, based on expected production volume, Domino’s prepares a set number of Dough balls and then keeps them fresh by covering them in Saran Wrap and placed in the refrigerator. At point of order, a dough ball is then flattened for pizza making.

Sauce

Once the dough ball is flattened, the Domino’s worker uses a scoring tool to place divots into the dough. The little marks on the dough allows the tomato sauce to adhere to the pizza dough.

Cheese and Other Ingredients

The White contraption you see in the picture is a measuring and spreading tool for cheese – it accurately holds the specified amount of cheese for the pizza size and then it is spun to spread the cheese evenly over the pizza. This process is semi-automated, which means the tool does most of the work and the employee just has to put the cheese into the white cheese measuring tool and spreader.

Image may be NSFW.

Clik here to view.

Bake

Pizza is placed in the oven. As the pizza is placed, the Domino’s employee starts a timer. The timer is critical because it tells the Pizza Tracker that the “Prep” step is complete, but it also signals the Tracker that the customer’s order is now in the “Bake” step.

The oven below is hard to see, but there’s a large moving horizontal oven below. The pizza is placed at the beginning and it rolls toward the right. As the pizza moves toward the right and exits the oven, the timer is then triggered and that tells the Pizza Tracker that the “Bake” step is complete and now the customer’s order is in the “Box” step.

Image may be NSFW.

Clik here to view.

Box

Pizza to Box Matching Process

When the pizza rolls off the oven, it is placed in a box that with the customer’s order label on it. This part of the process matches the customer’s pizza with the correct box with the customer’s information on it. This process follows a one-piece flow approach: take a pizza, put a pizza. By doing a single piece flow approach to pizza to box matching, the chances of pizza switcheroo defects are lower (a customer get’s another customer’s order).

Image may be NSFW.

Clik here to view.

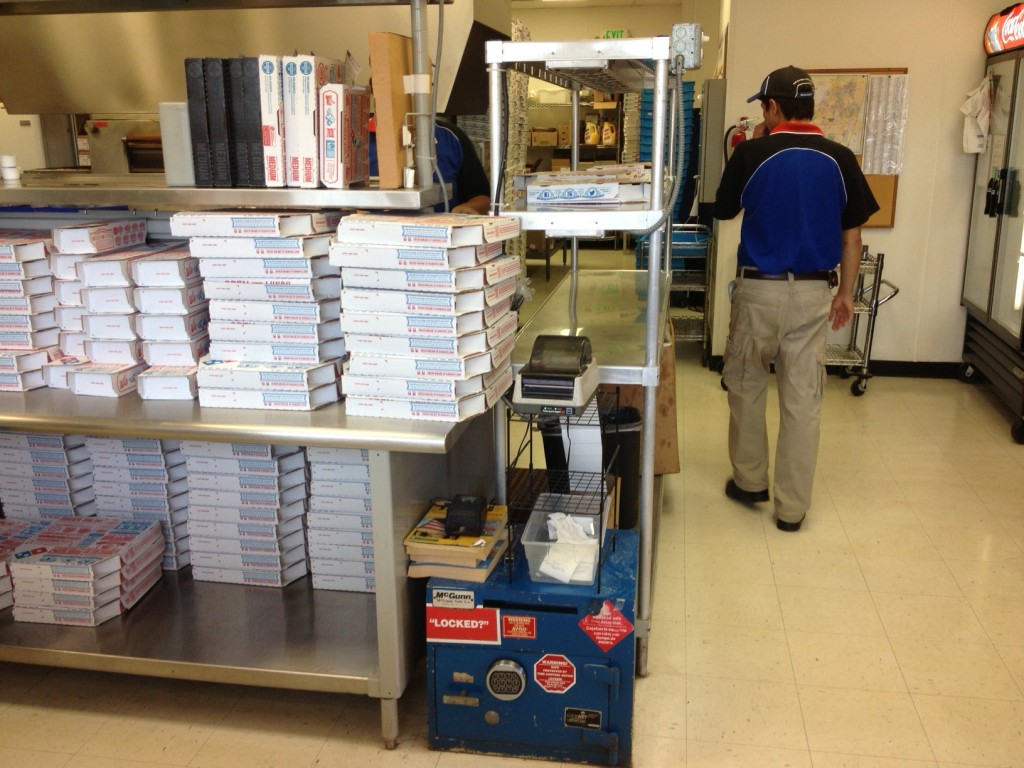

Pizza Packing

At this step, the Domino’s employee walks to the rack, places the pizza to the correct box. Once the pizza is packed, it waits for driver to pick up the pizza for delivery.

Delivery

Do you see the label maker toward the bottom of the rack? When the label is printed, that’s the signal to the Pizza Tracker that the customer’s order is no in the “Delivery” state.

Image may be NSFW.

Clik here to view.

Here’s a picture of the labels up close so you can see how pizzas are matched to the correct customer box. Let me explain each of the numbers in the label.

- 349041 is my order number

- 2/2 means that this is Box 2 of 2, which means there should be a Box 1 of 2 also, which completes the customer’s order.

- The letter “C” means Carry Out.

- The timestamp of when the customer’s order arrived and this is used to track average time to make a pizza, as well as the overall order arrival to pizza delivered process.

- Toward the bottom is the customer’s Name.

Image may be NSFW.

Clik here to view.

If there are other items in the order besides pizza, the box label will capture that also. This customer, for example, ordered Sprite with their 2 pizzas.

Image may be NSFW.

Clik here to view.

Looking at the Customer view of the pizza tracker and what actually happens behind the scenes in the kitchen of Domino’s pizza can give us a fuller picture of what it takes to deliver good service and how the Pizza Tracker is successful in the eyes of the customer. While the back-end process is nothing new, novel, or innovative, the way the status is portrayed to the customer – the interface – is the novel and innovated part of the process.

This is more than just lipstick on a pig – in many ways, the pizza tracker is the product because that is what the customer interacts with.

Fascinating. Are you hungry yet?

The post Where’s My Pizza? Behind The Scenes at Domino’s Pizza Tracker appeared first on shmula.

Clik here to view.

Clik here to view.

Clik here to view.

Clik here to view.

Clik here to view.

Clik here to view.

Clik here to view.

Clik here to view.